Bobby Chen – Applied Science

Abstract

Prehospital emergency care is challenging and can expose patients to secondary injuries from hazardous shocks and vibrations during ambulance travel on uneven roads. Addressing the issue of unwanted z-axis acceleration, a proposed scaled-down physical prototype of an ambulance stretcher, incorporating a damping mechanism, was developed and tested. The comparison between the prototype and the control model demonstrated that the implementation of air dashpots and compression springs effectively reduced z-axis acceleration. Specifically, the z-axis acceleration of the prototype was approximately 12% less than that of the control model. The findings presented in this paper provide a foundation for future researchers to build upon, offering insights toward resolving the vibration issue in ambulance stretchers.

Introduction

Emergency medical services (EMS) providers administer care to patients within dynamic and challenging environments. Due to the unpredictable nature of prehospital emergency care, patients are exposed to an elevated risk of errors and potential harm. These risks include secondary injuries caused by dangerous shocks and vibrations that are transmitted to the patient as the ambulance travels over uneven road surfaces (Dhamande et al, 2023). Although EMS providers employ injury-prevention techniques like securing patients to stretchers, these measures do not diminish the vibrations transmitted to the stretcher (Dhamande et al, 2023).

Damping mechanisms limit vibratory motion, such as mechanical oscillations, by dissipating energy. Previous studies have investigated the integration of damping mechanisms into ambulance stretchers to reduce the transmission of harmful vibrations to patients (Gawade et al, 2022, Malvezzi et al, 2021). When incorporating spring-mass-damper systems between the chassis and stretcher, mathematical models developed in MATLAB have shown that the modified stretcher exhibits reduced acceleration in the z-direction compared to the vehicle’s acceleration, signifying a less harsh impact on the patient (Gawade et al, 2022). The extent to which the vertical acceleration magnitude is reduced can be assessed by comparing it to a scenario where the stretcher is rigidly mounted in the ambulance (Malvezzi et al, 2021). Although researchers have proposed theoretical solutions, there is a scarcity of patents and research papers addressing the vibration issue in ambulances (Dhamande et al, 2023).

This paper aims to advance the field by showcasing the design, construction, and testing process of a scaled-down physical prototype derived from a theoretical solution. The proposed spring-mass-damping mechanism, incorporating air dashpots and compression springs, is assessed in comparison to its non-utilization.

Materials and Methods

Figure 1. The scaled-down prototype

The scaled-down prototype representing the ambulance stretcher, shown in Figure 1, measures 28 cm in length, 14 cm in width, and stands at a height of 9 cm. Constructed with a wooden surface, the apparatus is reinforced by four sets of Hillman steel compressions springs and air dashpots, comprising its damping mechanism. The primary damping mechanism consists of four Hillman steel compression springs, each with a diameter of 20.63 mm and serves as the initial contact point with the ground. Springs are attached to the four corners of wooden surface using Gorilla wood glue.

Operating in conjunction with these springs is the secondary damping mechanism, comprised of four air dashpots. Each air dashpot is constructed from two Karjiaja 3 mL plastic syringes and a MECCANIXITY 3 mm diameter metal rod. From one syringe, the plunger is removed to extract the rubber stopper. The rubber stopper is then attached to the end of the metal rod using Gorilla super glue. Similarly, a second rubber stopper is extracted from the other syringe, punctured to create a small hole, and slide onto the metal rod. To create an unobstructed barrel, one of the syringes has its tip and finger flanges removed using a wire cutter. The metal rod with rubber stoppers is inserted into the syringe barrel, and the second rubber stopper is affixed with super glue to seal the opening. Finally, the syringe’s tip is plugged with Crayola modeling clay and sealed using 3M duct tape. The assembled dashpots are attached to the wooden surface by gluing the metal rod to the underside of the wood at the four corners adjacent to the springs, towards the center of the wooden surface.

The prototype is compared with a control model, which comprises an apparatus of identical dimensions but is supported by wooden blocks instead of the damping mechanism, see Figure 2. The wooden blocks are attached to the wooden surface using Gorilla wood glue.

Figure 2. The control model

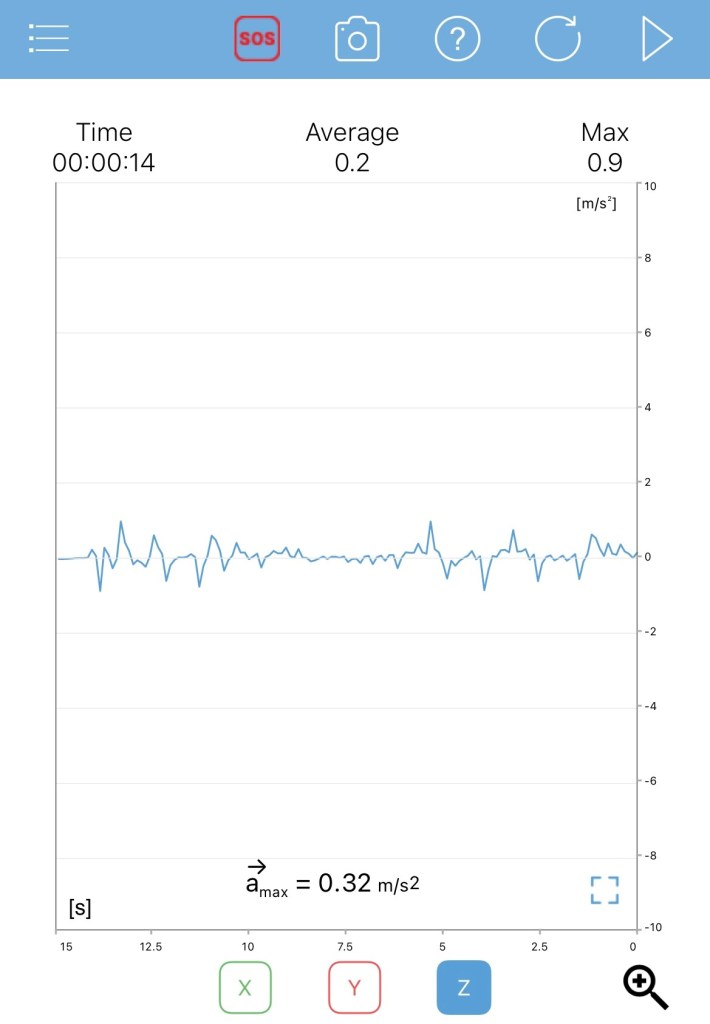

Following the creation of the scaled-down physical prototype and the control model, both subjects underwent testing in identical conditions. To measure the acceleration in the z-axis, an iPhone equipped with the Vibrometer app was strapped onto the top of the wooden surface of the control model. The subject was subsequently positioned on a level surface, and a force was applied in five trials by striking the underside of the surface with a fist. Before beginning each trial, the subject was observed to be at rest. The same process was then repeated for the scaled-down physical prototype. Figure 3 shows a sample output from the Vibrometer app.

Figure 3. Vibrometer app measures ground movement in the z-axis

Results:

Table 1 displays the accelerations experienced by the control model due to applied force across five trials. The results show an average z-axis acceleration of 1.45 m/s2.

Table 1. Acceleration in Z-axis of Control Model

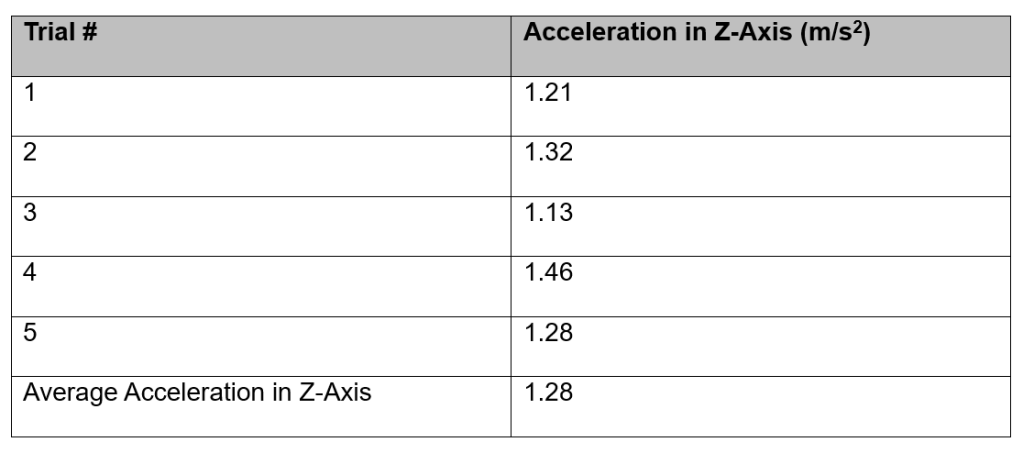

Table 2 displays the accelerations experienced by the scaled-down physical prototype due to applied force across five trials. The results show an average z-axis acceleration of 1.28 m/s2. The prototype experiences an average z-axis acceleration that shows a 12% decrease compared to the control model.

Table 2. Acceleration in Z-axis of Scaled-down Physical Prototype

Discussion

The comparison of results from testing the scaled-down prototype and the control model indicates the damping mechanism was effective in reducing z-axis acceleration. Although the test results adequately distinguished the effects of the damping mechanism, more accurate results could be achieved through modifications to the prototype and the testing procedure.

In theory, the air dashpots operated by counteracting upward applied force through the utilization of air pressure, thereby reducing z-axis acceleration. The damping effect in the air dashpots was achieved through the movement of plungers, driven by both applied force and the air pressure contained within the mechanism. However, the movement of the plungers attached to the prototype observed to be restricted by frictional resistance stemming from inadequate lubrication, which potentially hindered the attainment of more favourable results during testing. With proper lubrication, future testing of the prototype could produce results with a greater reduction in z-axis acceleration.

Future testing could also incorporate procedural improvements that better simulate real-world conditions and produce more accurate results. The testing procedure employed for this project involved a force that was manually applied. Consequently, the applied force was potentially inconsistent for each trial, leading to an inaccurate comparison of the prototype and the control model. To improve the testing procedure, the prototype and control model could both be strapped to the center console of a car and tested simultaneously. The car could drive at a uniform speed along the same road stretch in all trials, reducing variables that might distort the results while closely emulating real-world conditions.

Conclusion

This research paper presents a scaled-down physical prototype of an ambulance stretcher equipped with a damping mechanism, which incorporates air dashpots and compression springs to reduce z-axis acceleration. The results of this project reveal an approximate 12% decrease in z-axis acceleration, validating the effectiveness of the proposed theoretical solution, showcasing its potential value in enhancing patient safety in future ambulance stretcher designs. Overall, the findings provide a foundation for future researchers to build upon.

References

Dhamande, Laxmikant S., and Vishal B. Jadhav. “Vibration Reduction in Ambulance Using Modified Stretcher with Vibration Absorber.” SpringerLink, Springer Nature Singapore, 13 Dec. 2023, https://link.springer.com/chapter/10.1007/978-981-99-4721-8_14#:~:text=It%20was%20observed%20that%20with,amplitude%20of%20vibration%20by%20150%25.

Gawade, Akash Arjun, et al. “Design and Analysis of Stabilizing Ambulance Stretcher.” SpringerLink, Springer Nature Singapore, 3 Aug. 2022, https://link.springer.com/article/10.1007/s41403-022-00356-w.

Malvezzi, Fernando, et al. “Parameter Optimization for a Vibration Attenuation System on Ambulance Stretchers.” Vibroengineering Procedia, Extrica, 21 May 2023, https://www.extrica.com/article/21994.